Create Your First Project

Start adding your projects to your portfolio. Click on "Manage Projects" to get started

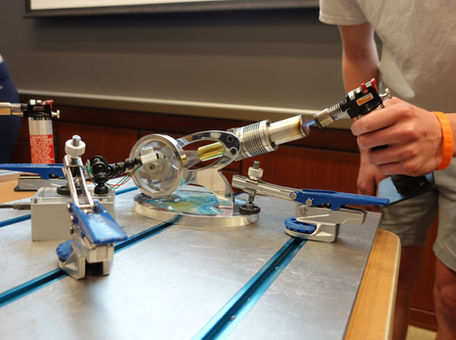

Stirling Engine

Location

Philadelphia, PA

Date

January-May 2025

Project type

Course

Collaboration

Solo

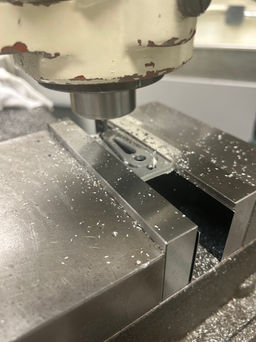

I created this engine as the sole project of Penn’s Machine Design and Manufacturing course during the spring semester of 2025. The flywheel’s atom design drove the inspiration of the design, with the rest of the components intended to be modern themed, with curving edges and an emphasis on negative space. Each component was designed using SolidWorks prior to its fabrication, making use of splines and ellipses to create the customized parts to complement the flywheel. They are compiled in an assembly of the engine, which uses a number of mates and constraints that allow for accurate motion of the engine in SolidWorks. I fabricated each of these parts in Penn’s Precision Machining Lab, primarily with Prototrak Mills (using both manual and CNC pathing) and lathes. Precise tolerancing was necessary for smooth, efficient, and fast operation. All components required a minimum precision of +/- 5 thousandths of an inch, in some cases needing a one-thou tolerance. The engine has a polished finish on the key metallic surfaces to give a clean and futuristic appearance. The colorful section at the base of the engine is a milled pocket filled with blue, gold, and white epoxy resin. The engine runs via application of a blow torch to the hot end, and clocked a speed of ~1400 RPM during testing.